Research Highlights

Bulking up Stem Cells to Get into the Healing Game

Institutions:

Rutgers University

Team:

Teryek, M., Jadhav, P., Bento, R., and Parekkadan, B.

Disease Model:

Liver & Kidney Failure

Hydrogel:

VitroGel® MSC

Mesenchymal stem cells (MSCs) can be grown up to scale and genetically tuned for therapeutic deployment using a combination of a xeno-free hydrogel system and a vertical wheel bioreactor.

In recent years we have been able to employ mesenchymal stem cells (MSCs) for a wide range of medical therapies. Because of their pluripotent capabilities, MSCs have the potential to restore tissue functionality––partially or fully––in cases of kidney or liver failure, and they have moreover been used for the treatment of diabetes, multiple sclerosis, and several other systemic diseases. One major hinderance to the wide-scale use of MSCs in these cases is to be able to grow, store, and deliver the cells in large enough quantities to meet clinical demand.

In this paper, a team of cell biologists from Rutgers University in New Jersey present a new technique to amplify the numbers of MSCs growing in the laboratory. The authors’ goal was to demonstrate how the growth of these cells could be supercharged in a bioreactor, which is a lab device in which scientists can transform raw materials into biochemical products, including into living cells. The factor by which a seed number of cells can be amplified into a larger number is called expansion. Here, the Rutgers team showed how this expansion could reach ten-fold or higher by the combination of a wheel-shaped bioreactor and the use of a potent hydrogel that supports and promotes cell growth.

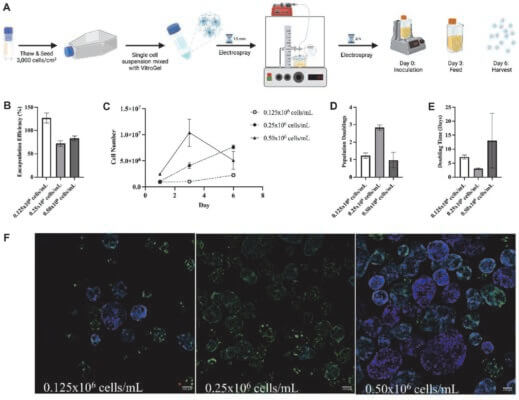

The authors first isolated MSCs from a human donor and then encapsulated them using an electrospray technique. To do this, the authors mixed MSC cell suspensions with TheWell Biosciences’ VitroGel® MSC, which is a xeno-free hydrogel system specifically developed to support three-dimensional (3D) cultures of MSCs. This hydrogel system was chosen because it can be used to make hydrogel cell beads for MSC scale-up techniques. The mixture was loaded into a 10-mL syringe and then dispersed using 4.55 kV of electrical potential at a rate of 20 mL per hour through a syringe pump. These encapsulated MSCs. Were transferred into a vertical wheel reactor, and cells were grown in a 90 mL volume for several days. The cells were “fed” with a constant supply of nutrients, such that the metabolic flux, or conversion rate of food into cells, could be calculated.

At various points in time, the authors sampled the bioreactor to see how well the MSCs were expanding in number. After six days, they harvested the cells. Using flow cytometry and microscopic imaging, they found that cell expansion was typically 10-fold or more, regardless of the starting number of cells. Importantly, the MSCs after this time frame retained their multipotent nature and their immunological characteristics. The cells furthermore could be genetically modified using viral vector transduction to create batches of cells with specific genotypes for targeted therapeutic use. In the end, this study demonstrated the huge power of VitroGel MSC hydrogel in a cleverly crafted bioreactor system to grow large amounts of viable and tunable MSC populations for biomedical use.

Read the publication:

Related Products: